Welcome to SDCAD Official Website! Email: admin@sdcadi.com

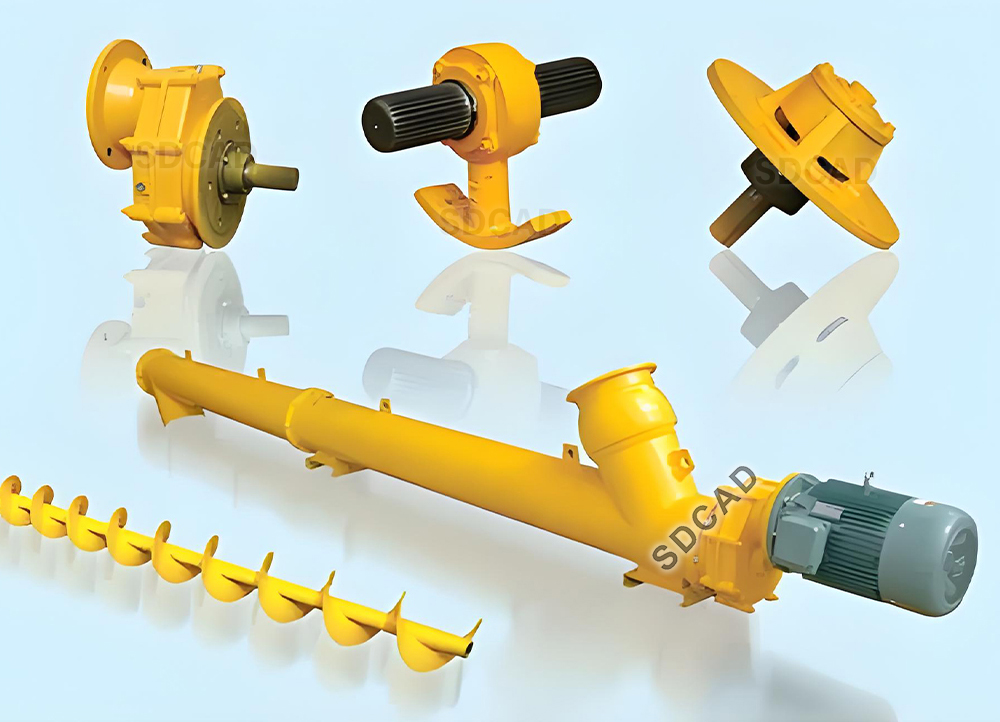

Screw Conveyor

The Screw Conveyor is a versatile and efficient material handling device widely used for conveying bulk powders and granular materials in industries such as cement, chemical, food, mining, and construction. It ensures steady, controlled flow of materials, making it ideal for horizontal or slightly inclined transport over short to medium distances.

Technology & Advantages

Designed with a rotating helical screw blade inside a sealed tube or trough, the screw conveyor moves materials smoothly without dust leakage. It offers uniform feeding, stable performance, and simple maintenance. The enclosed structure not only prevents contamination but also minimizes environmental pollution.

Made from carbon steel or stainless steel, the equipment is wear-resistant, corrosion-resistant, and built for long service life. Depending on the material and operating conditions, the conveyor can be customized in diameter, length, rotation speed, and screw pitch to ensure optimal performance.

|

Diameter |

Capacity |

|

114mm |

6 - 6.5T/h |

|

168mm |

20 - 25T/h |

|

219mm |

55 - 70T/h |

|

273mm |

75 - 100T/h |

|

323mm |

95 - 125T/h |

|

406mm |

120 -160T/h |

Applications

Screw conveyors are ideal for handling dry bulk materials such as:

-

Cement

-

Fly ash

-

Lime powder

-

Sand

-

Grain

-

Coal powder

-

Chemicals

-

Food ingredients

They are commonly used in concrete batching plants, bulk material silos, and mixing stations, functioning as an efficient link between storage, mixing, and packaging processes.

Working Principle

As the motor drives the screw shaft, materials are pushed forward along the conveyor’s casing by the rotating blades. Material movement is controlled and continuous, and can be adjusted by regulating the rotation speed. The conveyor can be configured for single or multiple inlet/outlet positions, and installed horizontally or at an incline as required.

Custom Options & Features

• Available in U-type or tube-type structure

• Customizable in length, diameter, and incline angle

• Optional anti-wear liners for abrasive materials

• Explosion-proof motors available for hazardous environments

• Reverse conveying function optional for specific applications

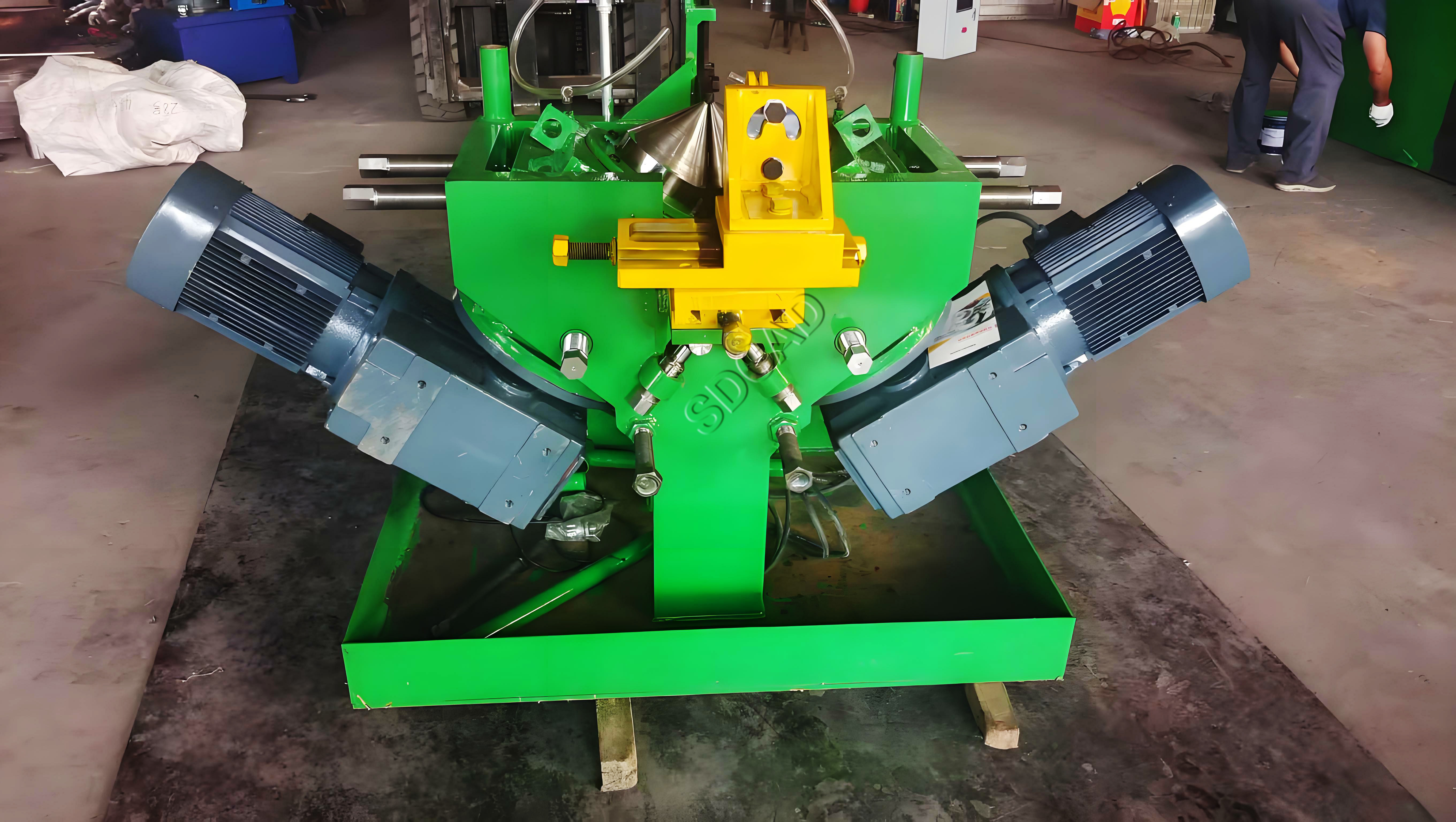

Parameters of Screw Blade Forming machine

|

Model |

3-80 |

3-100 |

|

Voltage |

380V 50Hz |

380V 50Hz |

|

Weight |

Approximately 0.6T |

Approximately 1T |

|

Size |

1500 * 400 * 600mm |

2000 * 550 * 1400mm |

|

Processing thickness |

2-8mm |

2-12mm |

|

Inner diameter range |

>12mm |

>20mm |

|

Outer diameter range |

<300mm |

<400mm |

|

Single side width of the mold |

180mm |

230mm |

|

Pitch |

80-200mm |

100-400mm |

|

Motor power |

3kw |

3kw |

|

Fuel tank capacity |

30L |

60L |

|

Fuel tank size |

300 * 200 * 500mm |

500 * 300 * 400mm |

|

pressure |

15T 10Mpa |

25T 20Mpa |

|

control |

Foot switch - dual signal |

Foot switch - dual signal |

Parameters of Continuous Screw Blade Forming machine

|

Item |

60-3 |

150-6 |

150.8 |

|

Material |

SPHC |

SPHC |

SPHC |

|

Plate width |

20-60mm |

20-150mm |

20-150mm |

|

Plate thickness |

2-3mm |

26mm |

2-8mm |

|

Rolling blade inner hole error |

<±3mm |

<±3mm |

<±5mm |

|

Rolling blade out diameter |

50.300mm |

60.750mm |

60-750mm |

|

Rolling blade out diameter error |

<±5mm |

<±5mm |

<±5mm |

|

Rolling blade pitch |

60-300mm |

50.800mm |

50-800mm |

|

Rolling blade pitch error |

<+5mm |

<±5mm |

<±5mm |

|

Working method |

Two rolling wheels working simultaneously |

Two rolling wheels working simultaneously |

Two rolling wheels working simultaneously |

|

Operating method |

Machine screw adjustment |

Machine screw adjustment |

Machine screw adjustment |

|

Total power |

8.5KW |

18KW |

35.5KW |

|

Total weight |

3 tons |

3.8 tons |

4.5 tons |

|

Equipment composition |

Spiral blade machine host, mechanical loading table, hydraulic shears, power distribution cabinet |

Spiral blade machine host, mechanical loading table, hydraulic shears, power distribution cabinet |

Spiral blade machine host, mechanical loading table, hydraulic shears, power distribution cabinet |

Social Media

Page Copyright: SHANDONG CAD INDUSTRY MACHINERY EQUIPMENT CO. LTD.