Welcome to SDCAD Official Website! Email: admin@sdcadi.com

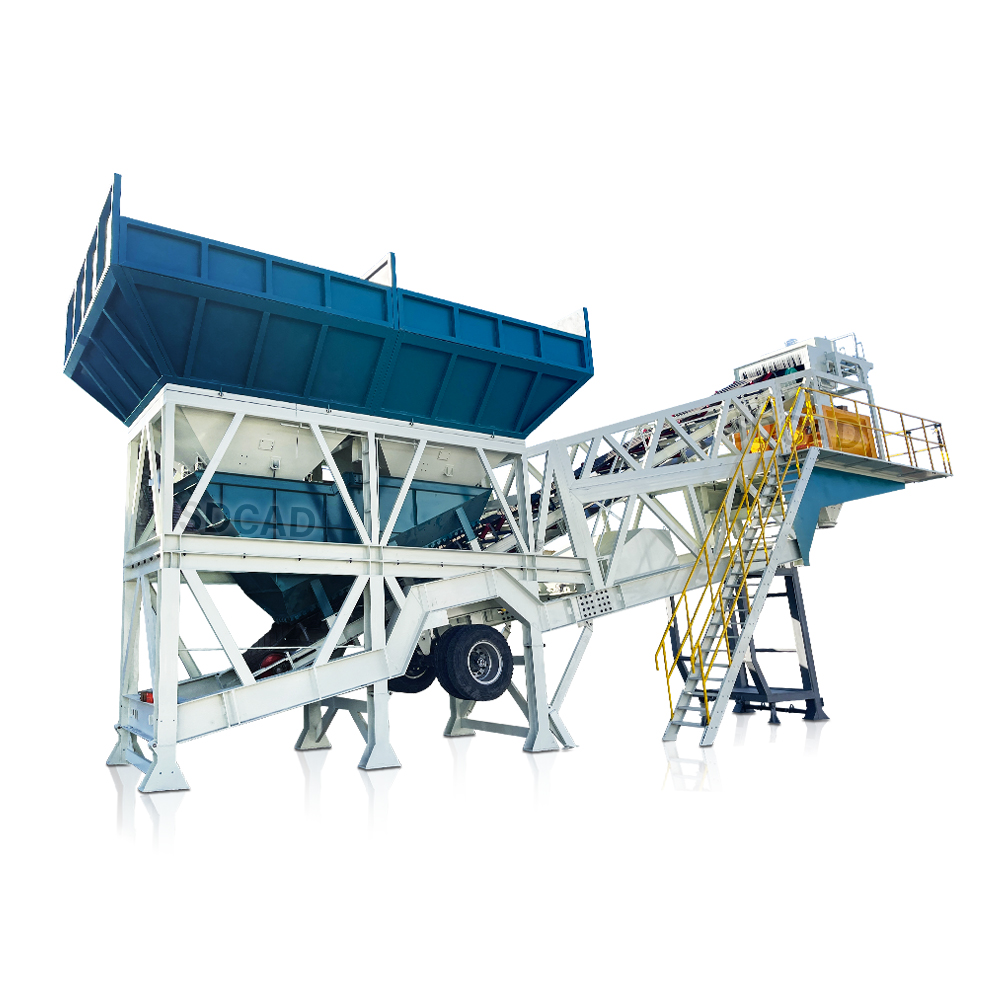

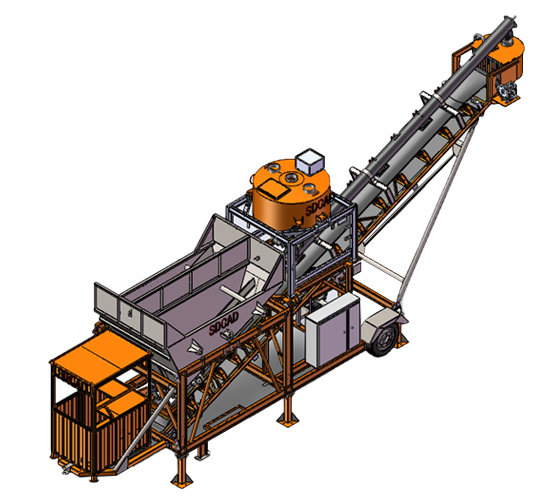

Mobile Concrete Batching Plant

The mobile concrete mixing station installs the control room, batching machine conveyor and metering system on one plane, and has material storage, weighing, conveying, mixing, unloading and fully automatic control systems.

Specifications

|

Model |

YHZS25 |

YHZS35 |

YHZS50 |

YHZS75 |

YHZS100 |

||

|

Theoretical Production (m³/h) |

25 |

35 |

50 |

75 |

100 |

||

|

Mixer |

JS500 |

JS750 |

JS1000 |

JS1500 |

JS2000 |

||

|

Mixer Power (kw) |

18.5kw |

18.5kw |

2*18.5kw |

2*30kw |

2*37kw |

||

|

Aggregate Maximum Particle(mm) |

60/40 |

60/40 |

80/60 |

80/60 |

80/60 |

||

|

Feeding Capacity(L) |

750 |

1150 |

1500 |

2250 |

3000 |

||

|

Discharge Capacity(L) |

500 |

750 |

1000 |

1500 |

2000 |

||

|

Aggregate Bin Capacity(m³) |

2*3 |

2*3 |

2*3 |

4*5 |

4*5 |

||

|

Aggregate conveyor belt |

800 |

1200 |

1200 |

2400 |

3200 |

||

|

Belt conveying Capacity (t/h) |

300 |

300 |

200 |

600 |

600 |

||

|

Screw conveyor Capacity(t/h) |

40 |

40 |

40 |

40-70 |

40-70 |

||

|

Breaking bucket capacity (m³) |

4.0 |

4.0 |

4.0 |

4.0 |

4.2 |

||

|

Installed capacity (kw) |

67 |

79 |

56 |

120 |

170 |

||

|

Weighing range |

Aggregate |

200~800 ±2% |

250~1200 ±2% |

250~1200 ±2% |

(600~2000) ±2% |

(700~2400) +2% |

|

|

Cement |

70~350 ±1% |

100~500 ±1% |

100~500 +1% |

(200~800) ±1% |

(350~1200) ±1% |

||

|

Water |

50~200 ±1% |

50~200 ±1% |

Flow meter |

(100~400) ±1% |

(150~550) +1% |

||

|

Additive |

10~30 ±1% |

10~30 ±1% |

Flow meter |

(6~30)±1% |

(10~50%) ±1% |

||

Features at a Glance

Model: HZSY25 ~ HZSY100

Capacity: 25~ 100 m³/h

Discharge Size :500~2000L

Provide technical support 24 hours.

Engineers to guide the installation and operation

Advantages

1. Integrated trailer design, can be driven on the road, Easy to transfer.

2. Self-research concrete mixer, reliable operation, high quality wear-resistant parts, longer life

3. Compact structure, small footprint, scientific arrangement of components, easy maintenance.

4. High-quality accessories, more stable operation, low failure rate.

5. Computer control, easy to operate, can realize manual, semi-automatic and full-automatic multiple control modes.

6. All materials are measured separately, with high output and measurement accuracy.

7. Mixer options include planetary mixer and double horizontal shaft mixer

8. All the equipment load into one 40HQ

9. Fully automatic operation, one person can operate the entire device, saving labor.

10. Customization is acceptable,Not limited to solutions, output, electrical brands, etc

Social Media

Page Copyright: SHANDONG CAD INDUSTRY MACHINERY EQUIPMENT CO. LTD.