Welcome to SDCAD Official Website! Email: admin@sdcadi.com

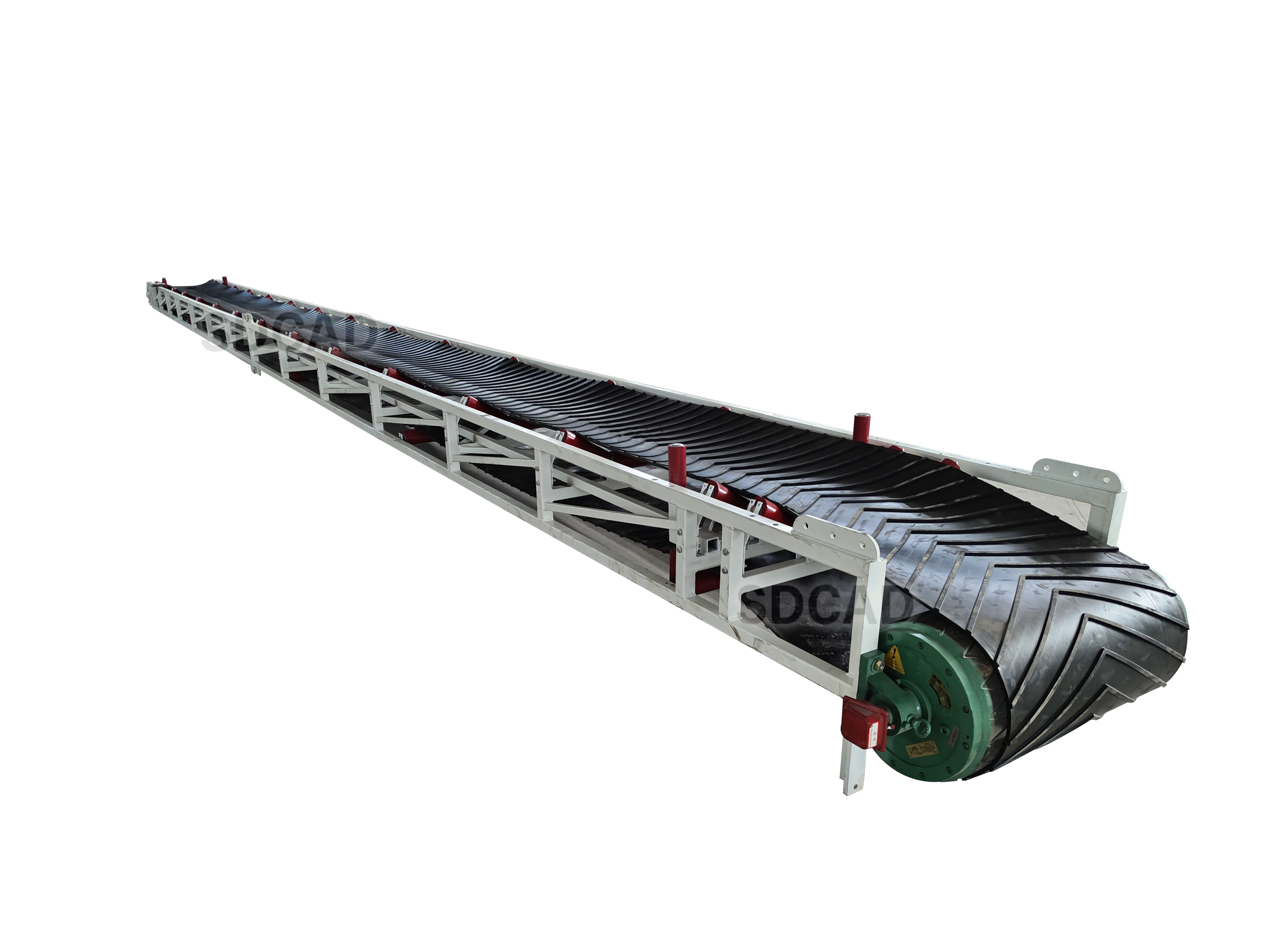

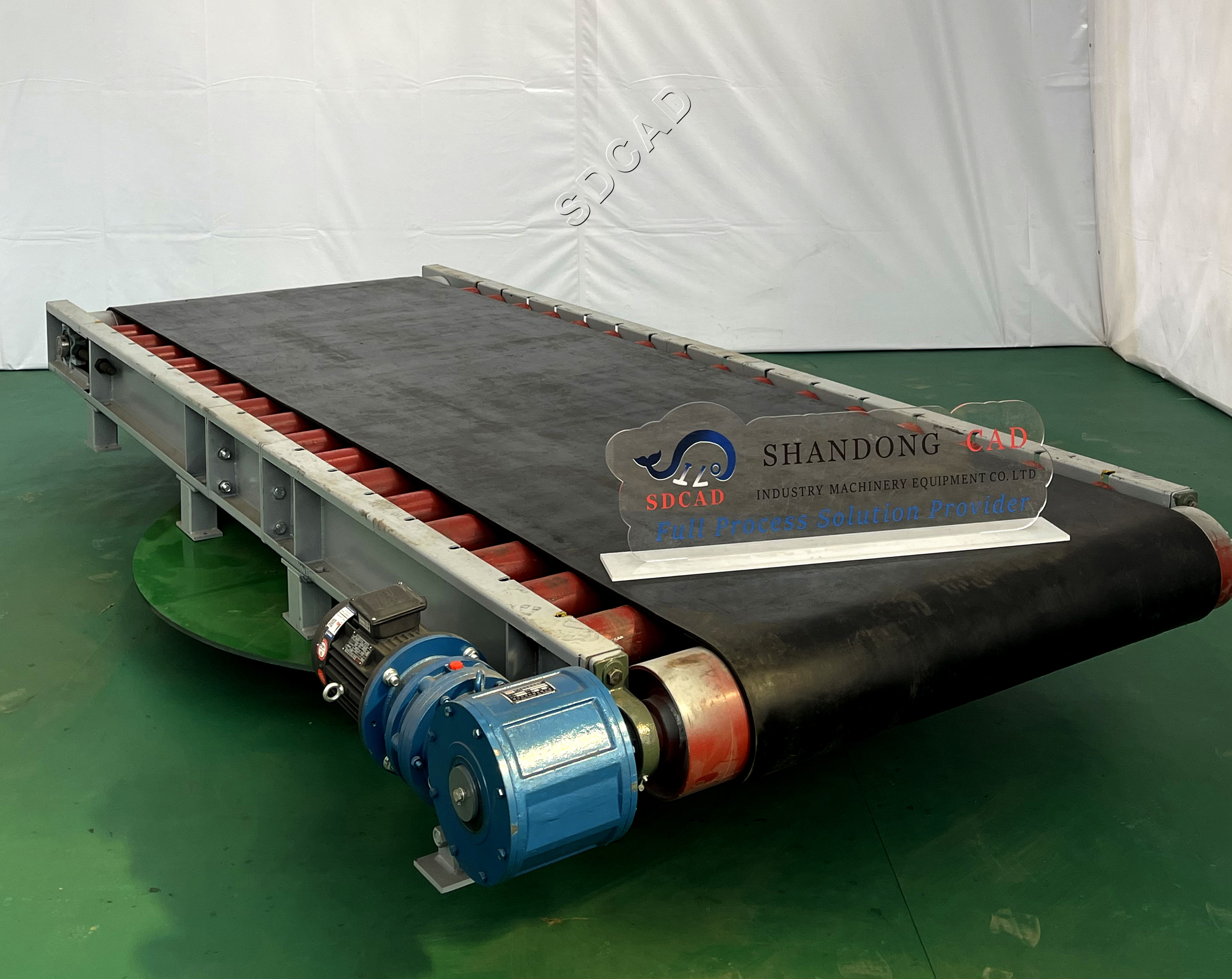

Belt Conveyor

Belt conveyor is a kind of material handling equipment with strong adaptability, apply for conveying bulk density less than 1.67t/ m³, it is mostly used for powder, granular, small lump materials and bagged materials, such as sand, ore, coal, cement and other loose materials.

Specifications

|

Belt width |

Belt length(m)/Power(kw) |

Belt speed |

Capacity(t/h) |

||

|

I(l/kw) |

II(L/kw) |

III(L/kw) |

|||

|

B400 |

≤12/1.5 |

12-20/2.2-4 |

20-25/3.5-7.5 |

1.3-1.6 |

40-80 |

|

B500 |

≤12/3 |

12-20/4-5.5 |

20-30/5.5-7.5 |

1.3-1.6 |

80-190 |

|

B650 |

≤12/4 |

12-20/5.5 |

20-30/7.5-11 |

1.3-1.6 |

130-320 |

|

B800 |

≤6/4 |

6-15/5.5 |

15-30/7.5-15 |

1.3-1.6 |

280-550 |

|

B1000 |

≤10/5.5 |

10-20/7.5-11 |

20-40/11-12 |

1.3-2 |

440-850 |

|

B1200 |

≤10/7.5 |

10-20/11 |

20-40/15-30 |

1.3-2 |

660-1200 |

Social Media

Page Copyright: SHANDONG CAD INDUSTRY MACHINERY EQUIPMENT CO. LTD.