Welcome to SDCAD Official Website! Email: admin@sdcadi.com

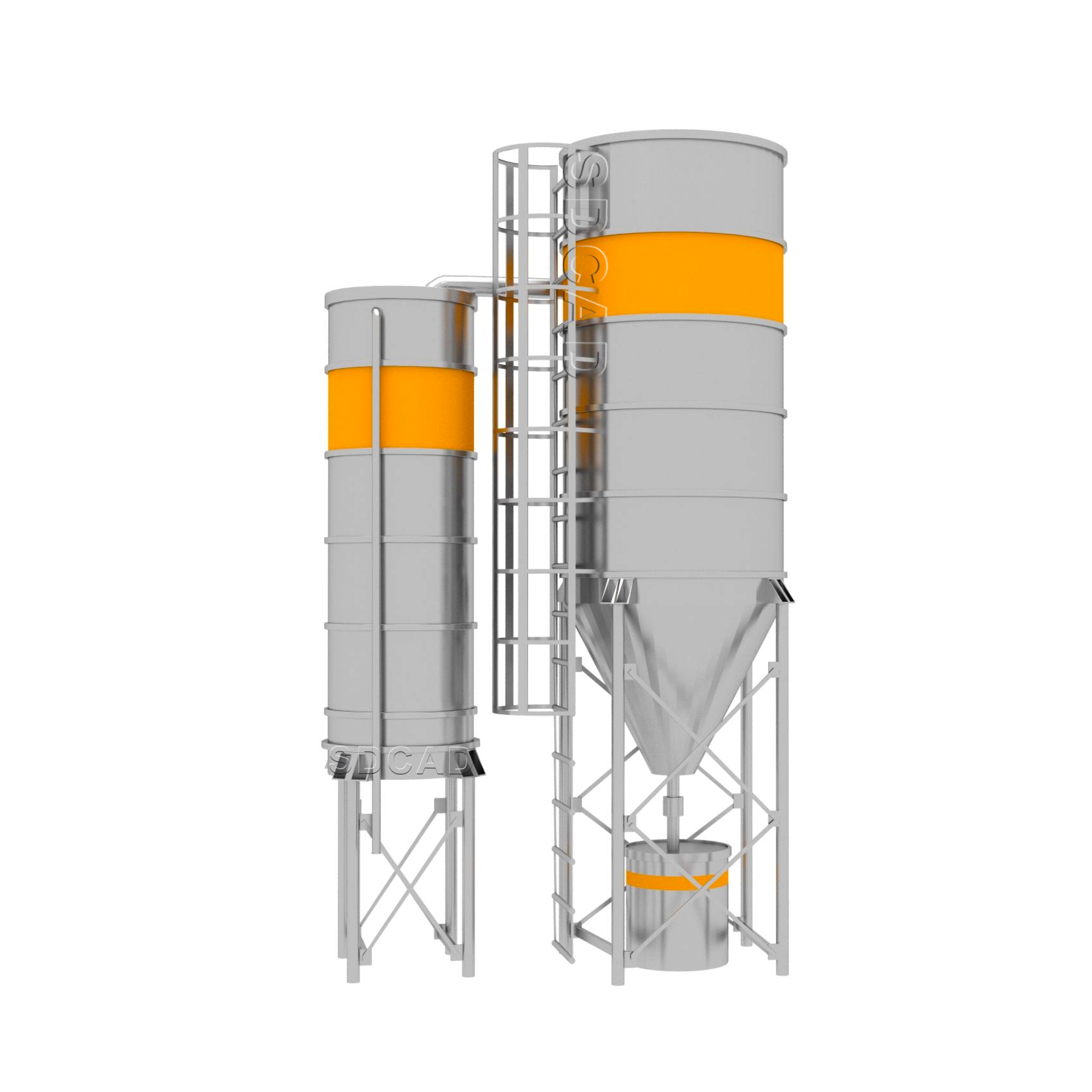

Welded Silo

SDCAD Welded Silo is a fully assembled, monolithic storage unit primarily used for the containment of bulk powders and granular materials. Unlike bolted or sectional silos, the welded silo is constructed as a single integrated body, which minimizes potential leakage points and provides excellent structural integrity. It is typically made of carbon steel or stainless steel, depending on the material stored and specific application requirements.

The cylindrical body and conical bottom are welded together to form a seamless internal space, which facilitates smooth material discharge and reduces residue buildup. Welded silos are often equipped with accessories such as level indicators, pressure relief valves, manholes, and aeration pads to ensure controlled filling and discharge. The bottom outlet is usually designed to connect with screw conveyors, rotary feeders, or pneumatic conveying systems.

These silos are suitable for applications in cement plants, chemical processing, plastic resin storage, and other industrial settings where continuous, dust-tight storage is essential. The robust, rigid structure also makes them well-suited for installation in fixed locations where transportability is not a priority.

Social Media

Page Copyright: SHANDONG CAD INDUSTRY MACHINERY EQUIPMENT CO. LTD.