Welcome to SDCAD Official Website! Email: admin@sdcadi.com

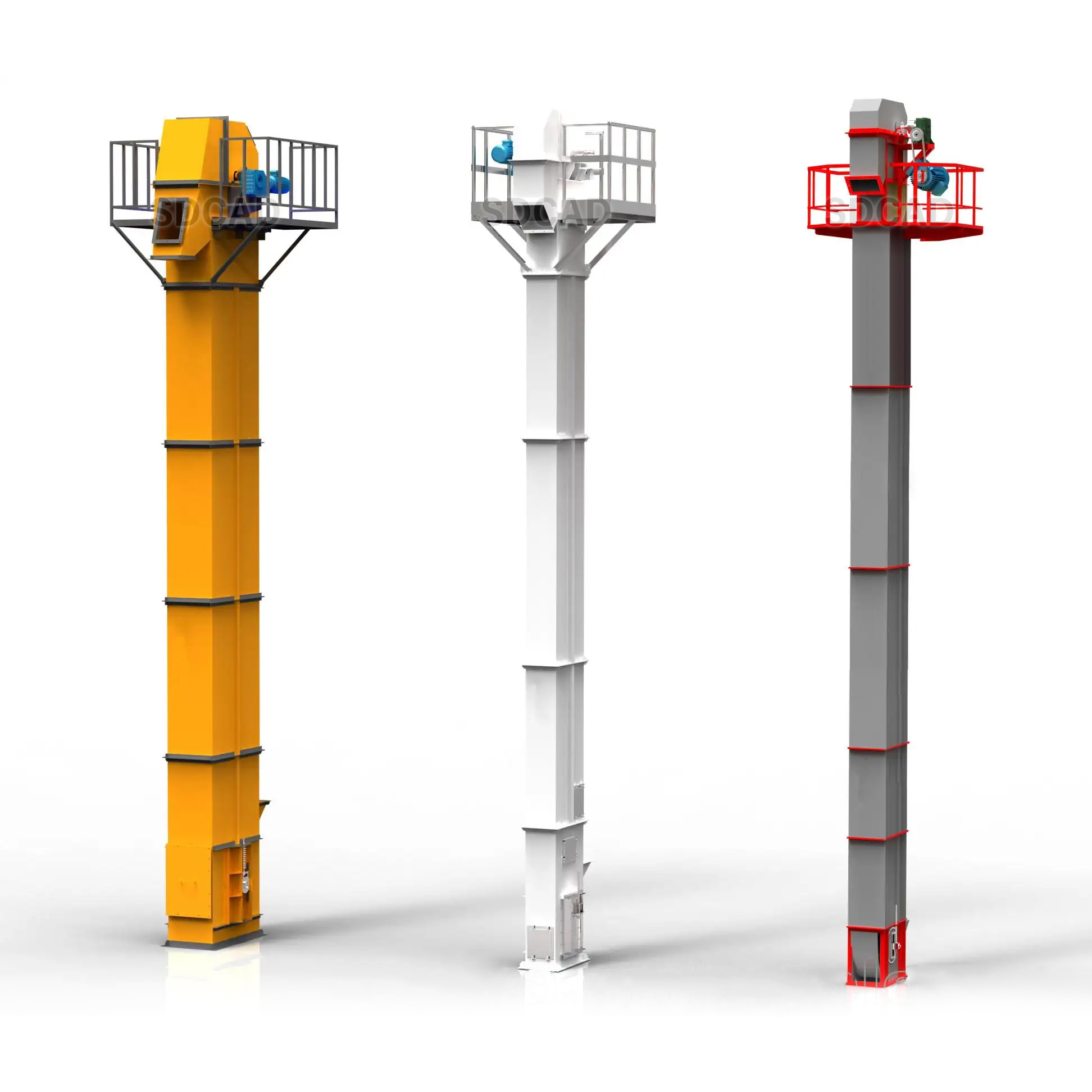

Bucket Elevator

Bucket Elevator in cement plant, also called cement bucket elevator, is mechanical conveying equipment, mainly apply for the vertical lift of powder, particles like limestone, coal, gypsum, clinker, clay, raw meal, cement, pulverized coal, etc. in general, cement bucket elevator work with cement crusher, raw mill, cement mill, and other cement equipment. As for the types of bucket elevator, there are chain bucket elevator and belt bucket elevator. According to the different speeds, bucket elevators can be divided into centrifugal discharge, gravity discharge, and mixed discharge. The chain bucket elevator and belt bucket elevator are available in SDCAD, you can customize a suitable type as you need.

Advantages

Low driving power

The bucket elevator adopts inflow-type feeding, induced-type feeding, and large-capacity hopper intensive arrangement. There is almost no material return and digging when the material is lifted, so there is little invalid power.

Wide lift area

This bucket elevator has fewer requirements on the types and characteristics of materials. It can apply for not only general powdery and small granular materials, but also materials with greater grinding properties. It has good sealing and less environmental pollution.

Good operation reliability

Reasonable design and processing ensure the reliability of the whole operation, and the failure-free time exceeds 20,000 hours.Higher lifting height, the bucket elevator is running smoothly, so it can reach a higher lifting height.

Long service life

The feed of the bucket elevator adopts the inflow type, and the phenomenon of squeeze and collision between the materials rarely occurs. This bucket elevator ensures that materials are not scattered during feeding and unloading, which reduces mechanical wear.

Specifications

|

|

|

|

TD Belt Elevator |

Plate Chain Elevator |

Chain Elevator |

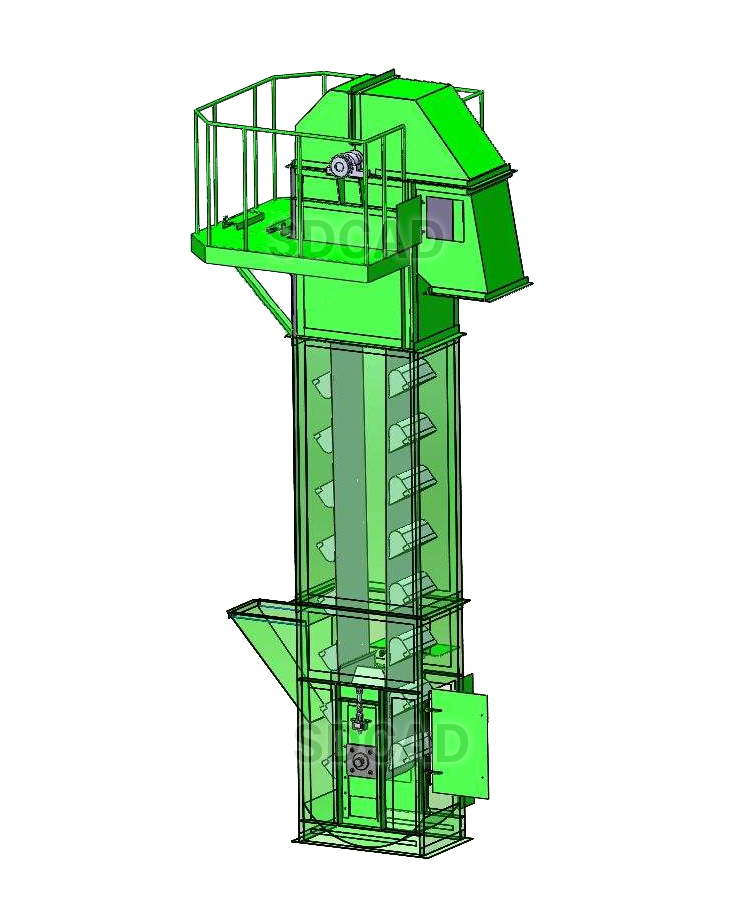

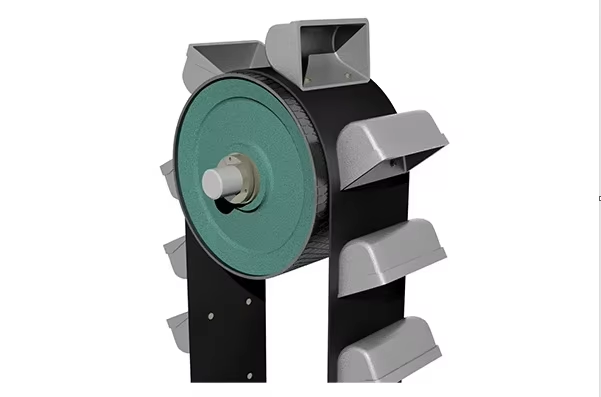

Working Principle

The bucket elevator is composed of a running part (hopper and traction belt), an upper section with a transmission drum, a lower section with a tension drum, an intermediate casing, a driving device, a backstop brake device, etc. It is suitable for conveying powder, granular and small lump-free and semi-polished bulk materials with loose density ρ <1.5t / m³, such as coal, sand, coke, cement, crushed ore, etc.

Social Media

Page Copyright: SHANDONG CAD INDUSTRY MACHINERY EQUIPMENT CO. LTD.