Welcome to SDCAD Official Website! Email: admin@sdcadi.com

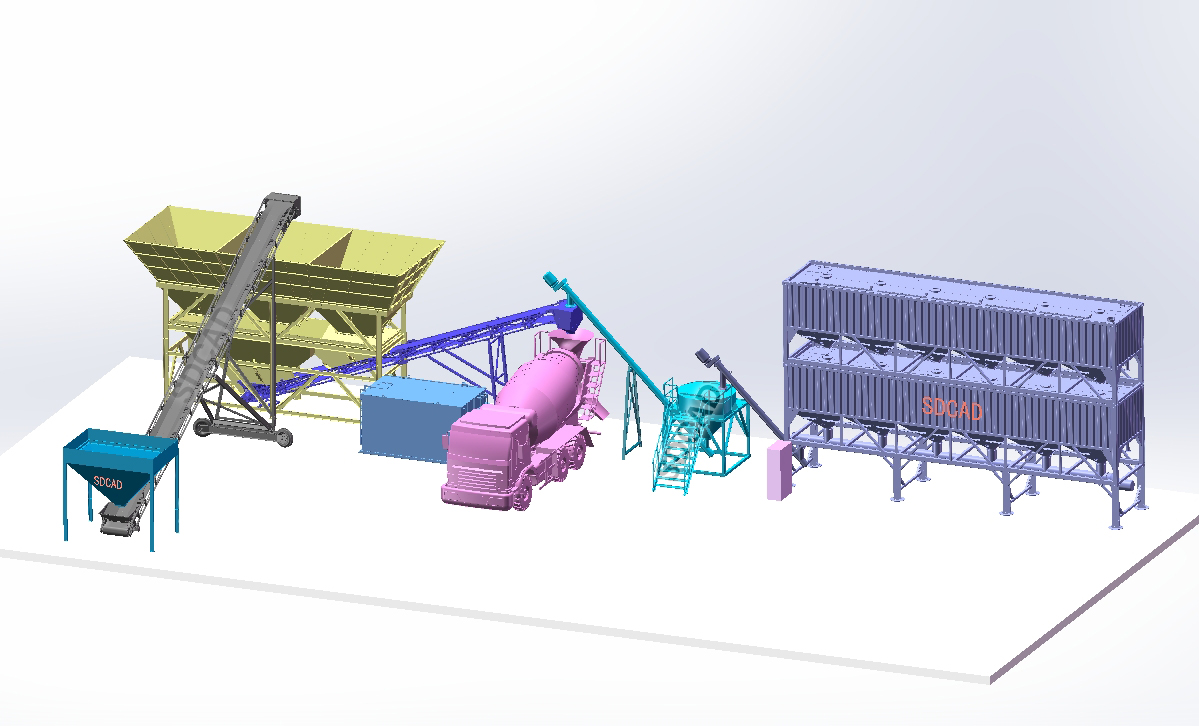

Dry Concrete Batching Plant

Working Principle

Dry concrete batching plants have sand, gravel, and cement feeding to batching plant that pass the numerical or manual scale. Then all the raw materials are discharged into a chute into the truck. At the same time, the water is weighed, or volume metered and discharged into the mixer truck through the same charging tank. At last, all the material mixed and transported to the site.

Advantages

- It has higher capacity and lower energy consumption because can be mixed without water

- The cooperation between the dry batching plant and the mixer truck can increase productivity and save time.

- The fresh can be used because of the mixer trucks arrive at the construction site.

- It shortens the construction and enhances productivity.

- It’s got lower power consumption when compared to the wet mix plant.

- Operating costs of dry-batch are relatively low

- All ow so be mixed more efficiently.

- It could be the short time period of maintenance needed when compared with wet mix plants.

- As in other mixing plants, such as mobile and stationary the dry plant is also automated.

- If the site is quite long, it is an ideal choice for dry manufacturers. While the mixer truck going to the construction site, it may keep the rotation order to prevent tampering, hardening of the mixed and to ensure the freshness of the materials.

- Dry batch vegetation is much-welcomed modern production equipment that is constantly significantly assist in the development and

development of modern roads, bridges and various construction works.

Specifications

|

Model |

Capacity |

|

D-Mix50 |

50m³/h |

|

D-Mix75 |

75m³/h |

|

D-Mix90 |

90m³/h |

|

D-Mix120 |

120m³/h |

|

D-Mix150 |

150m³/h |

|

D-Mix180 |

180m³/h |

Social Media

Page Copyright: SHANDONG CAD INDUSTRY MACHINERY EQUIPMENT CO. LTD.